By Patricia McDaniels

Energy security, global warming, food versus fuel: these are the terms political insiders and John Q. Public and Jane Q. Citizen are tossing around at cocktail parties and church potlucks. But while the energy debates rage, the University of Tennessee is forging ahead toward a homegrown solution.

With financial help from state government and additional private investment, UT is aggressively pursuing statewide implementation of a business model for biobased transportation fuel, specifically, commercially competitive production and distribution of cellulosic ethanol. Dr. Kelly Tiller, agricultural economist and director of operations for the UT Office of Bioenergy Programs, predicts that once fully realized, this next-generation biofuel industry (as opposed to corn-based ethanol production) stands to significantly improve Tennessee’s economy while simultaneously reducing the transfer of wealth from consumers’ pockets through gas pumps across the Volunteer State to Swiss banks and foreign investment houses. What’s more, as Tiller has stated in testimony before a Senate conference, UT’s efforts combined with the resources at the Oak Ridge National Laboratory put Tennessee front and center in the race for research-and-development solutions to the national problem of energy security.

After Hurricane Katrina in 2005, gas prices shot up dramatically across the nation. By 2006, when prices were consistently hovering around the $2.50 mark, people were clamoring for a national solution to the high cost of transportation fuel. In 2007 future-minded researchers with the UT Institute of Agriculture’s AgResearch program, Tiller among them, boldly presented a plan that many had envisioned for years.

Nicknamed the Tennessee Biofuels Initiative, the plan to produce cellulosic ethanol from locally grown feedstocks like switchgrass quickly gained support across the state. Folks from farmers to business entrepreneurs, ranking politicians, and soccer moms were interested in investing in transportation energy security for the state and nation.

With the endorsement of Governor Phil Bredesen, the Tennessee General Assembly allocated $70 million over a 5-year period to the university to construct a pilot-scale biorefinery. Its purpose is to prove the feasibility of technology to produce commercially competitive cellulosic ethanol and to develop useful co-products that will further bolster the state’s economy with new jobs. Some $8 million of the funds is earmarked for research and development of a farm-based system of feedstock production to support the biorefinery, as well as an eventual network of additional refineries operating in communities across the state.

If $2.50-a-gallon gas put the national mood on a slow burn just 2 years ago, averages that topped $4.00 a gallon after Hurricane Ike last September caused the national psyche to blow. With high energy costs and the world financial crisis, the UT AgResearch vision for energy security and economic development is both welcome and timely.

As a land-grant university, UT is charged with research, education, and technology transfer. In the biofuels initiative, a substantial effort has been mounted to ensure that the state’s farming community can profitably support a biofuels industry while also ensuring the environmental soundness or sustainability of energy crops.

Research plots across the state are testing varieties of switchgrass for their suitability as a fuel crop, and additional research examines production and harvest practices and carbon sequestration. Biosystems engineers are designing and evaluating equipment for planting and harvesting, and plant scientists are working to isolate genetic traits to enhance switchgrass performance.

Because a crop must be ready when the biorefinery is first operational, UT is already working with selected farmers in East Tennessee. UT Extension agents and biofuels specialists are teaching 16 contract farmers the ins and outs of switchgrass production, and with their help, UT Extension is developing a body of publications and firsthand knowledge of how to establish and grow the new crop.

The pool of contract farmers was established because a market for switchgrass as biomass did not exist. “We needed some farmers to grow something they had no experience with, so we are working closely with sixteen select producers to help them manage their risk,” said Dr. Clark Garland, UT Extension economist who helped write the farmer agreements.

In spring 2008 UT contracted for 723 acres of switchgrass. Once the biorefinery is fully operational, some 4,000 additional acres may be needed for research and other purposes. If the business plan is implemented across the state, many more farmers and acres are expected to participate in feedstock production.

Ken Goddard and Jon Walton, UT Extension switchgrass specialists, were engaged to help the farmers establish the feedstock supply for the biorefinery. “It’s not that easy to establish. The first year some switchgrass fields can be full of weeds and pretty thin,” says Goddard. “By the second or third year, the switchgrass fields with adequate plant populations can naturally out-compete other plants.” Goddard transferred from West Tennessee after years of working with experimental crops of switchgrass to help the East Tennessee farmers get their grass crop up and growing.

At the same time that Garland, Walton, and Goddard were working to establish a feedstock for the biorefinery, Tiller was toiling on the tasks of biorefinery construction and economic development. While the state’s investment is sizable, the university hoped to supplement it with funds from technical collaborators. And in July 2008, DuPont Danisco Cellulosic Ethanol (DDCE) signed on to build the biorefinery.

The pilot plant and process development unit—a research facility that enables experimentation at a larger-than-laboratory scale, as well as faster adjustments to process components—will be located at the Niles Ferry Industrial Park in Monroe County.

A project of the U.S. and European industrial giants DuPont and Danisco, DDCE leverages more than $140 million of investment and more than 10 years’ research and development of integrated cellulosic ethanol technologies that use various nonfood feedstocks. In Tennessee, DDCE expects the pilot biorefinery to produce 250,000 gallons of cellulosic ethanol annually from switchgrass and corncobs.

If all goes as anticipated, the pilot-scale biorefinery will prove the commercial feasibility of producing cellulosic ethanol, and private investors will step in to build and manage a new biobased fuel industry for the state, perhaps as early as 2012. The university will have found another way to improve the lives of Tennesseans, and just as important, the state and nation will be another step closer to energy security.

And the gas shortages of 2008? They may become an obscure footnote to history for future Tennesseans.

Breaking New Ground

The sun shone brightly on October 14 as the University of Tennessee took another step toward leading the nation in biofuel research.

Amid a gathering of more than 200 business leaders, farmers, scientists, and politicians—including Governor Phil Bredesen, Senator Bob Corker and Representatives Zach Wamp and John J. Duncan Jr.—Genera Energy LLC, a limited liability company of the UT Research Foundation, collaborated with DuPont Danisco Cellulosic Ethanol LLC to break ground for an innovative pilot-scale biorefinery and state-of-the-art research and development facility for cellulosic ethanol, or ethanol from nonfood sources.

The first-of-its-kind facility, located near Vonore, Tennessee, will use nonfood biomass (corncobs, fiber, and switchgrass) as feedstocks for transportation fuel, so officials used a tractor and a no-till seed drill to officially break ground for the site. Utilizing DDCE’s cellulosic ethanol technology and the UT Institute of Agriculture’s expertise in cellulosic feedstock production and co-product research, the facility is expected to be a catalyst for a new biofuel industry for the state.

Governor Bredesen believes the state has an opportunity to take the leadership position in alternative fuels. “We are facing serious energy challenges from local to global,” he said. “When it comes to facing the challenges of the future, Tennessee isn’t just talking the talk about clean energy technology, we’re walking the walk—rolling up our sleeves and getting to work.”

The governor said the alternative fuels industry could be an economic engine for Tennessee. “The bottom line is that this plant and this partnership are going to do a lot of good for Tennessee’s future,” he said.

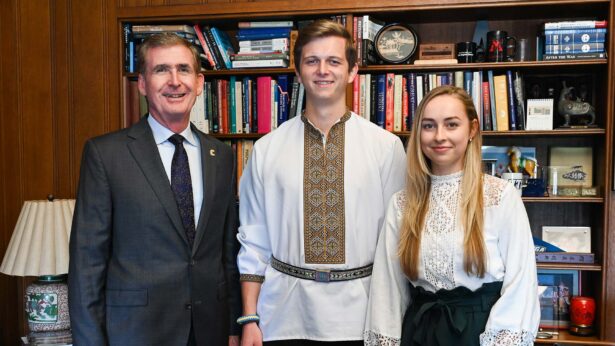

For his part, UT President John Petersen is proud of the role the university is playing in this initiative. “It is an important part of our responsibility and our mission as a land-grant university—to impact the state’s economy and serve the public, in addition to educating the young people of Tennessee,” he said.

DDCE President Joseph Skurla praised the collaboration as a healthy union of cutting-edge technology, supply economics, and transportation logistics. “DuPont Danisco has the technology package that will lead the way in the market,” Skurla said. “We are ready to scale up, we have economics that can’t be beat, and with the University of Tennessee and the farmers of this great state, we have a winning team that is going to help deliver sustainable nonfood biofuels to the market on an accelerated schedule.”

The pilot plant is expected to produce cellulosic ethanol by the end of 2009.

The biorefinery’s construction and switchgrass production are the first major components of the UT Biofuels Initiative, a farm-to-fuel business plan developed by UT Institute of Agriculture researchers. The initiative models a biofuels industry with multiple commercial facilities supplied by locally grown feedstock and capable of supplementing 30 percent of Tennessee’s current petroleum consumption.